Fiberglass R10 to R38 for Metal Buildings/Pole barns

Lowest Price Fiberglass Insulation for Metal Buildings and Pole Barns

Looking for top-quality fiberglass insulation at the best possible price? You're at the right place. At Insulation4Less, we guarantee the lowest prices on R-10, R13, R19, and R25 fiberglass insulation for metal buildings and pole barns -- whether it's White VRR+ or Unfaced. If you find a better price elsewhere, we want to know. Let us match it.

- Lowest-Price Guarantee -- We aim to offer the most competitive rates in the market.

- Broad R-value Options - Available in R-10 through R38, including versatile banded liner systems with screws and strapping included.

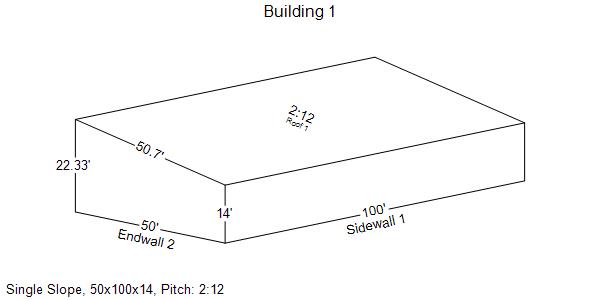

- Hassle-Free Shopping Experience -- Custom shopping cart calculates exact roll lengths and quantities for your building, or you can pick "Buy by Rolls."

- Expert Support & Fast Delivery -- Our team will call you within a few business days to confirm your order and arrange delivery.

Delivery Time: 1 - 2 Weeks

Instructions: For R30, R36, or R38, choose ‘Custom Cuts’ from the Select an Option dropdown below.

![]() = image

= image

Roof installation instructions

Wall installation instructions

Accessories

Double Sided tape (1.5" x 180') ![]()

Minimum product order: $500 (shipping not included)

Why Buy Fiberglass Insulation from I4L?

Lower Cost

Pressure-Free Shopping

Point and click ordering - We handle all the details, so you can focus on your project without any sales pressure.Credibility You Can Trust

With independent reviews on Site Jabber and an A+ rating with the BBB, you can trust I4L to deliver top-quality products and service.

R-values Available: 13, 19, 25, 30, 36 and 38

Protect Your R

Prodex Total is the perfect complement to fiberglass metal building insulation. Here's why:

Installing Prodex Total between the fiberglass and metal sheeting, keeps the fiberglass dry; thereby, preserving the R-value of the the fiberglas over time. ![]() Learn how Prodex Total compares to fiberglass insulation for metal buildings or how it compares to fiberglass insulation for pole barns in our detailed side-by-side guides.

Learn how Prodex Total compares to fiberglass insulation for metal buildings or how it compares to fiberglass insulation for pole barns in our detailed side-by-side guides.

Introduction to Fiberglass Insulation for Metal Buildings and Pole Barns

When it comes to insulating metal buildings and pole barns, fiberglass insulation stands out as one of the most cost-effective and efficient solutions. These types of structures, often used for agricultural, industrial, and storage purposes, are particularly vulnerable to extreme temperature fluctuations and moisture issues. Proper insulation not only ensures comfort and energy efficiency but also protects the structural integrity of these buildings.

In this article, we’ll explore why fiberglass insulation is the ideal choice for metal buildings and pole barns and highlight the key benefits it offers for building owners and operators.

Why Choose Fiberglass Insulation for Metal Buildings and Pole Barns?

Fiberglass insulation is the go-to solution for insulating metal structures and pole barn buildings due to its versatility, affordability, and superior thermal performance. Its lightweight nature makes it easy to install on metal frames or within pole barn cavities, while its moisture and mold resistance ensures long-term durability. Additionally, fiberglass insulation is non-combustible, providing an added layer of safety for buildings used to store equipment, vehicles, or flammable materials.

Whether you’re constructing a new pole barn or retrofitting an existing metal building, fiberglass insulation delivers reliable performance in a variety of applications.

Benefits of Fiberglass Insulation for Metal Buildings and Pole Barns

1. Improved Temperature Control

Metal and pole barn buildings are highly conductive, making them prone to extreme temperature swings. Fiberglass insulation provides excellent thermal resistance (R-value), keeping interiors cooler during summer and warmer in winter. This consistent temperature regulation improves comfort and functionality.

2. Energy Efficiency

By minimizing heat transfer, fiberglass insulation reduces the energy demand for heating and cooling systems. This leads to lower energy bills and a more sustainable building. For property owners looking to enhance energy efficiency, fiberglass is an excellent choice.

3. Condensation Prevention

Metal buildings are particularly susceptible to condensation, which can lead to rust, corrosion, and water damage. Fiberglass insulation acts as a barrier, reducing moisture buildup and protecting the structural components of your building. Enhance this feature and protect your fiberglass from moisture by installing Prodex Total between the fiberglass and the metal sheeting.

4. Noise Reduction

Fiberglass insulation also helps dampen external noise, making metal buildings and pole barns quieter. This is especially beneficial for buildings near busy roads, farms, or industrial sites.

5. Cost-Effectiveness

Compared to other insulation options, fiberglass is one of the most affordable solutions available. It provides excellent performance at a fraction of the cost of more expensive alternatives, making it ideal for budget-conscious building projects.

6. Sustainability

Many fiberglass insulation products are made from recycled materials, making them an environmentally friendly option. By choosing fiberglass, you’re not only enhancing your building but also reducing your environmental footprint.

Why Insulate Your Metal Building or Pole Barn?

Without proper insulation, metal buildings and pole barns can experience significant heat loss, condensation issues, and higher energy costs. Fiberglass insulation solves these problems effectively, ensuring that your building remains comfortable, efficient, and protected from environmental challenges.

Boost Your Building's Performance with Fiberglass Insulation

Fiberglass insulation is the perfect choice for metal buildings and pole barns, offering a range of benefits, including energy efficiency, condensation control, noise reduction, and affordability. Whether you’re constructing a new structure or upgrading an existing one, installing fiberglass insulation is an investment that pays off in reduced energy costs, improved durability, and enhanced comfort. Turbo boost performance, by installing Prodex Total Insulation (insulation, radiant barrier, vapor barrier and air barrier in one product) between the fiberglass insulation and the metal sheeting.

Technical Information

Banded Liner System Data Sheet

Liner Banded System (R25, R30, R36 and R38 products): Provides leading-edge OSHA-compliant Fall Protection System and meets energy code requirements. A low permeance fabric serves as the vapor retarder preventing condensation, contributing to air barrier integrity, and providing a brighter resilient finish. Reduces noise transfer inside and outside the building, providing superior sound abatement.

- Meets Fire code

- GREENGUARD Certified

Insulation Core (fibers)

| Property | Test Method | Result |

| Thermal Resistance | ASTM C177/C518 | See R-value of item |

| Surface Burning | UL 723/ASTM E84 | Flame spread index <25 |

| Combustion Characteristics | ASTM E136 | Non-combustible |

| Water Vapor Sorption | ASTM C1104 | < 0.2% by volume |

| Fungi Resistance | ASTM C1338 | Passes - no growth exhibited |

| Corrosiveness | ASTM C665 | Passes |

| ||

VR-R+ Facing

Polypropylene / Scrim / Ployester

Meets ASTM C1136 Type 11, IV, VI

| FACING COMPOSITION | DESCRIPTION | VALUES (I-P) |

| White Film | Polypropylene | 12.6 lbs / 3000 ft2 |

| Adhesive | Flame Resistant | |

| Reinforcing | Tri-directional | MD: 4 / inch |

| Fiberglass | XD: 4 / inch | |

| Film | Metalized Polyester | 0.0005 inch |

| PHYSICAL PROPERTIES | TEST METHOD | VALUES (I-P) |

| Basis Weight | Scale | 14 lbs / 1000 ft2 |

| Permeance (WVTR) | ASTM E96 | <0.02 perm |

| Procedure A | (grains / hr*ft2*in Hg) | |

| Bursting Strength | ASTM D774 | 90 psi |

| Tensile Strength | ASTM D828 | MD: 35 lbs / inch |

| XD: 35 lbs / inch | ||

| Temp. & Humidity Resistance | ASTM C1258 | No Corrosion |

| No Delamination | ||

| Low Temperature Resistance | ASTM C1263 | Remains Flexible |

| 4 hours at -20°F (-29°C) | No Delamination | |

| High Temperature Resistance | ASTM C1263 Modified | Remains Flexible |

| 4 hours at 240°F (116°C) | No Delamination | |

| Mold Resistance | ASTM C1338 | No Growth |

| Dimensional Stability | ASTM D1204 | <0.5% |

| Light Reflectance | ASTM E1331 | 85% |

| FIRE TESTING | ASTM E84 / UL 723 | |

| Polypropylene Side | Polyester Side | |

| Flame Spread | 10 | 10 |

| Smoke Developed | 35 | 40 |

|

Metal Buildings

Pole Barns

Other Prodex Total Products to Consider

Recommended Prodex Products to use with Fiberglass

10M Prodex Total Plus 4 ft x 85.3 ft (341 sq ft)

48 INCH Prodex Total 5M Plus 4 ft x 175 ft (700 sq ft)

FAST ACTION Prodex Total 5M Plus 4 ft X 175 ft (700 sq ft)

72 INCH Prodex Total 5M Plus 6 ft x 100 ft (600 sq ft)

62 INCH FAST ACTION Prodex Total 5M Plus 5'2 X 125' (645 sq ft)

Fiberglass Insulation and Moisture Sensitivity :

- Fiberglass insulation's R-value decreases when exposed to moisture. The R-value comes from the air-pockets between the fibers, not the fibers themselves. As the air pockets fill with moisture, the R-values reduces.

- Moisture compromises the insulation's effectiveness in maintaining thermal performance.

Solution - Install Prodex Total between Fiberglass and metal sheeting

- Prodex Total is an insulation, radiant barrier, vapor barrier, and condensation eliminator in a single product.

- Prevents moisture from reaching the fiberglass insulation, ensuring it stays dry.

Resulting Benefit:

- Helps fiberglass insulation retain its thermal value by shielding it from moisture.

Technical data

Banded Liner System Data Sheet

Liner Banded System (R25, R30, R36 and R38 products): Provides leading-edge OSHA-compliant Fall Protection System and meets energy code requirements. A low permeance fabric serves as the vapor retarder preventing condensation, contributing to air barrier integrity, and providing a brighter resilient finish. Reduces noise transfer inside and outside the building, providing superior sound abatement.

- Meets Fire code

- GREENGUARD Certified

Insulation Core (fibers)

Property Test Method Result Thermal Resistance ASTM C177/C518 See R-value of item Surface Burning UL 723/ASTM E84 Flame spread index <25 Combustion Characteristics ASTM E136 Non-combustible Water Vapor Sorption ASTM C1104 < 0.2% by volume Fungi Resistance ASTM C1338 Passes - no growth exhibited Corrosiveness ASTM C665 Passes

- Formaldehyde-free

- Made with 99% natural materials - not acrylic

- Made in the U.S.A

- Uses a minimum of 65% recycled content - 41% being post-consumer

VR-R+ Facing

Polypropylene / Scrim / Ployester

Meets ASTM C1136 Type 11, IV, VI

FACING COMPOSITION DESCRIPTION VALUES (I-P) White Film Polypropylene 12.6 lbs / 3000 ft2 Adhesive Flame Resistant Reinforcing Tri-directional MD: 4 / inch Fiberglass XD: 4 / inch Film Metalized Polyester 0.0005 inch

PHYSICAL PROPERTIES TEST METHOD VALUES (I-P) Basis Weight Scale 14 lbs / 1000 ft2 Permeance (WVTR) ASTM E96 <0.02 perm Procedure A (grains / hr*ft2*in Hg) Bursting Strength ASTM D774 90 psi Tensile Strength ASTM D828 MD: 35 lbs / inch XD: 35 lbs / inch Temp. & Humidity Resistance ASTM C1258 No Corrosion No Delamination Low Temperature Resistance ASTM C1263 Remains Flexible 4 hours at -20°F (-29°C) No Delamination High Temperature Resistance ASTM C1263 Modified Remains Flexible 4 hours at 240°F (116°C) No Delamination Mold Resistance ASTM C1338 No Growth Dimensional Stability ASTM D1204 <0.5% Light Reflectance ASTM E1331 85%

FIRE TESTING ASTM E84 / UL 723 Polypropylene Side Polyester Side Flame Spread 10 10 Smoke Developed 35 40

Banded Liner System Data Sheet

Liner Banded System (R25, R30, R36 and R38 products): Provides leading-edge OSHA-compliant Fall Protection System and meets energy code requirements. A low permeance fabric serves as the vapor retarder preventing condensation, contributing to air barrier integrity, and providing a brighter resilient finish. Reduces noise transfer inside and outside the building, providing superior sound abatement.

- Meets Fire code

- GREENGUARD Certified

Insulation Core (fibers)

| Property | Test Method | Result |

| Thermal Resistance | ASTM C177/C518 | See R-value of item |

| Surface Burning | UL 723/ASTM E84 | Flame spread index <25 |

| Combustion Characteristics | ASTM E136 | Non-combustible |

| Water Vapor Sorption | ASTM C1104 | < 0.2% by volume |

| Fungi Resistance | ASTM C1338 | Passes - no growth exhibited |

| Corrosiveness | ASTM C665 | Passes |

| ||

VR-R+ Facing

Polypropylene / Scrim / Ployester

Meets ASTM C1136 Type 11, IV, VI

| FACING COMPOSITION | DESCRIPTION | VALUES (I-P) |

| White Film | Polypropylene | 12.6 lbs / 3000 ft2 |

| Adhesive | Flame Resistant | |

| Reinforcing | Tri-directional | MD: 4 / inch |

| Fiberglass | XD: 4 / inch | |

| Film | Metalized Polyester | 0.0005 inch |

| PHYSICAL PROPERTIES | TEST METHOD | VALUES (I-P) |

| Basis Weight | Scale | 14 lbs / 1000 ft2 |

| Permeance (WVTR) | ASTM E96 | <0.02 perm |

| Procedure A | (grains / hr*ft2*in Hg) | |

| Bursting Strength | ASTM D774 | 90 psi |

| Tensile Strength | ASTM D828 | MD: 35 lbs / inch |

| XD: 35 lbs / inch | ||

| Temp. & Humidity Resistance | ASTM C1258 | No Corrosion |

| No Delamination | ||

| Low Temperature Resistance | ASTM C1263 | Remains Flexible |

| 4 hours at -20°F (-29°C) | No Delamination | |

| High Temperature Resistance | ASTM C1263 Modified | Remains Flexible |

| 4 hours at 240°F (116°C) | No Delamination | |

| Mold Resistance | ASTM C1338 | No Growth |

| Dimensional Stability | ASTM D1204 | <0.5% |

| Light Reflectance | ASTM E1331 | 85% |

| FIRE TESTING | ASTM E84 / UL 723 | |

| Polypropylene Side | Polyester Side | |

| Flame Spread | 10 | 10 |

| Smoke Developed | 35 | 40 |

|

Other Prodex Products

Recommended Prodex Products to use with Fiberglass

10M Prodex Total Plus 4 ft x 85.3 ft (341 sq ft)

48 INCH Prodex Total 5M Plus 4 ft x 175 ft (700 sq ft)

FAST ACTION Prodex Total 5M Plus 4 ft X 175 ft (700 sq ft)

72 INCH Prodex Total 5M Plus 6 ft x 100 ft (600 sq ft)

62 INCH FAST ACTION Prodex Total 5M Plus 5'2 X 125' (645 sq ft)

Fiberglass Insulation and Moisture Sensitivity :

- Fiberglass insulation's R-value decreases when exposed to moisture. The R-value comes from the air-pockets between the fibers, not the fibers themselves. As the air pockets fill with moisture, the R-values reduces.

- Moisture compromises the insulation's effectiveness in maintaining thermal performance.

Solution - Install Prodex Total between Fiberglass and metal sheeting

- Prodex Total is an insulation, radiant barrier, vapor barrier, and condensation eliminator in a single product.

- Prevents moisture from reaching the fiberglass insulation, ensuring it stays dry.

Resulting Benefit:

- Helps fiberglass insulation retain its thermal value by shielding it from moisture.

Related products

10M Prodex Total Plus 4 ft x 85.3 ft (341 sq ft)

10M Prodex Total Plus 4 ft x 85.3 ft (341 sq ft)

View product

48 INCH Prodex Total 5M Plus 4 ft x 175 ft (700 sq ft)

Ship dimensions: L: 48" W: 24" H: 24" Lbs: 26

View product

FAST ACTION Prodex Total 5M Plus 4 ft X 175 ft (700 sq ft)

FAST ACTION Prodex Total 5M Plus 4 ft X 175 ft (700 sq ft)

View product